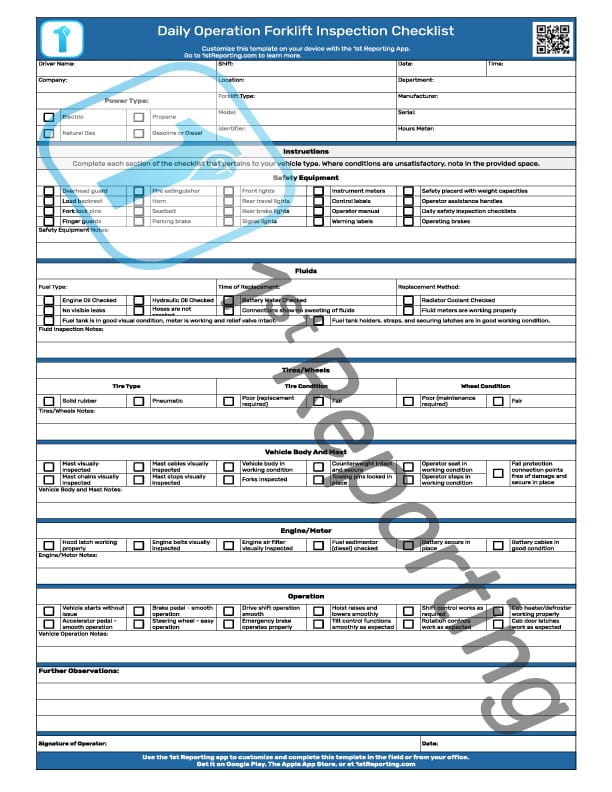

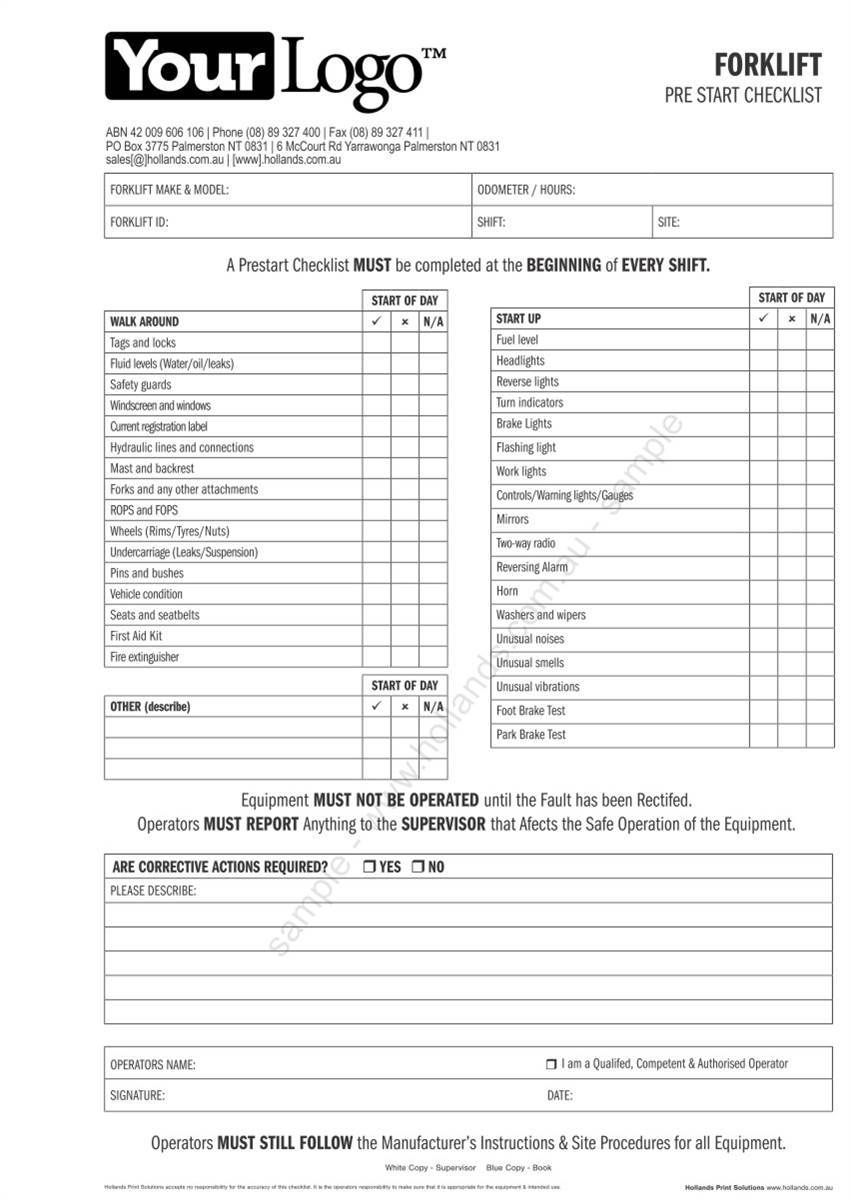

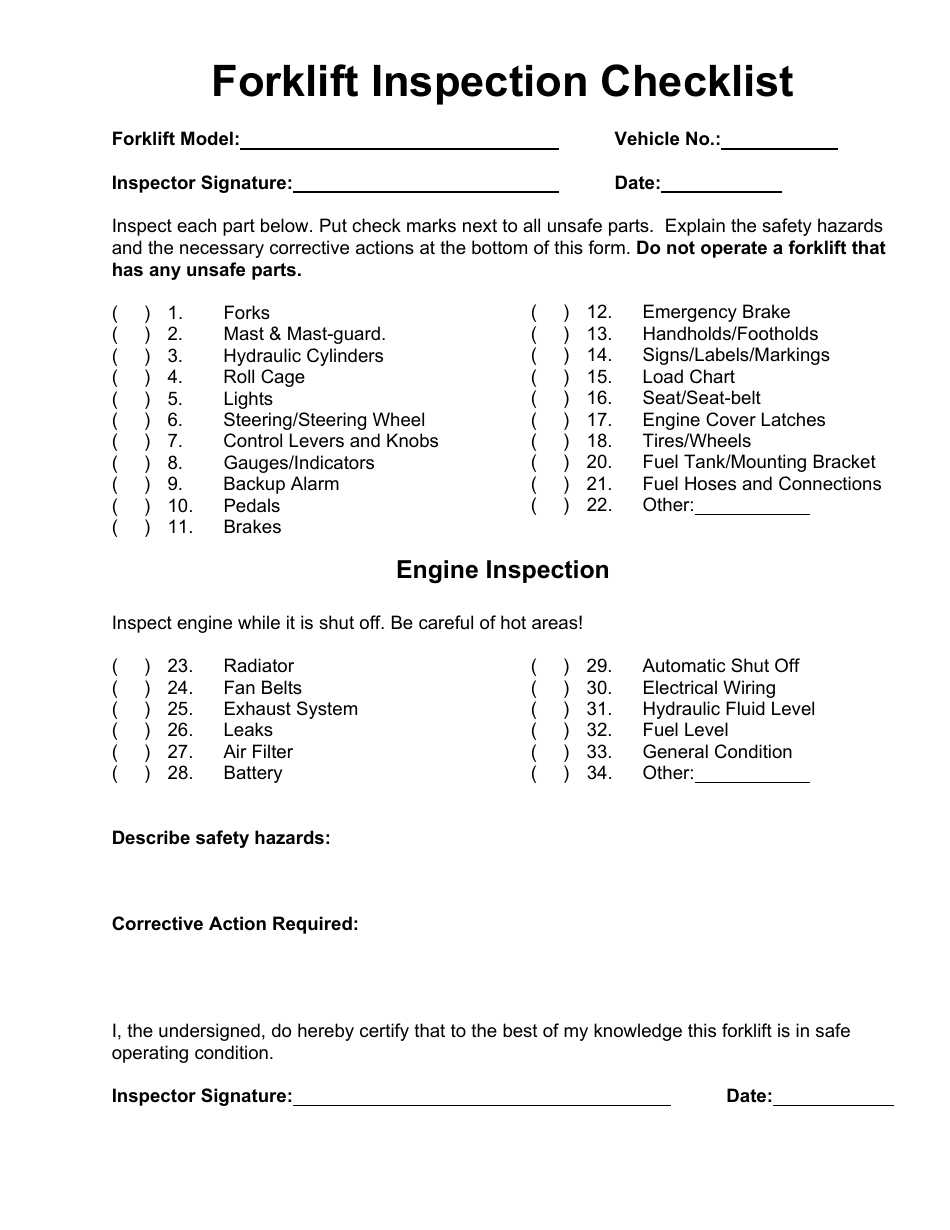

Printable Forklift Inspection Checklist - Web forklift safety page 2 of 2 operator's daily checklist: 09/2016 deficiency explanations indicate below which line item from the inspection checklist you are referencing. Web the use of a forklift inspection checklist helps to ensure that a forklift is being used safely. Carefully review each item and mark the corresponding checkbox to indicate compliance or note any observations and areas for improvement. Web forklift inspection checklist date & time forklift model and/or serial # supervisor name inspector name ok = good condition nr = needs repair or item needs review by a supervisor na = not applicable to this particular forklift cks battery & connections fluid level is adequate, vent caps in place; Connectors are not cracked or. Each segment consists of a brief description below to help you train your team members on each. Web the checklist for forklift inspection includes many segments. If the forklift is found to be unsafe, the condition must be reported immediately to the supervisor and repaired. Web daily forklift inspection checklist.

Printable Forklift Safety Checklist Printable Templates

Because your team completes these inspections every single day, it’s easy to become complacent and start going through the motions. Web exterior inspection section 1.

24+ Free Printable Forklift Inspection Checklist Templates Sample PDF

You can use this template and framework for your own forklift inspections. Web this checklist is designed to conduct a comprehensive safety inspection of the.

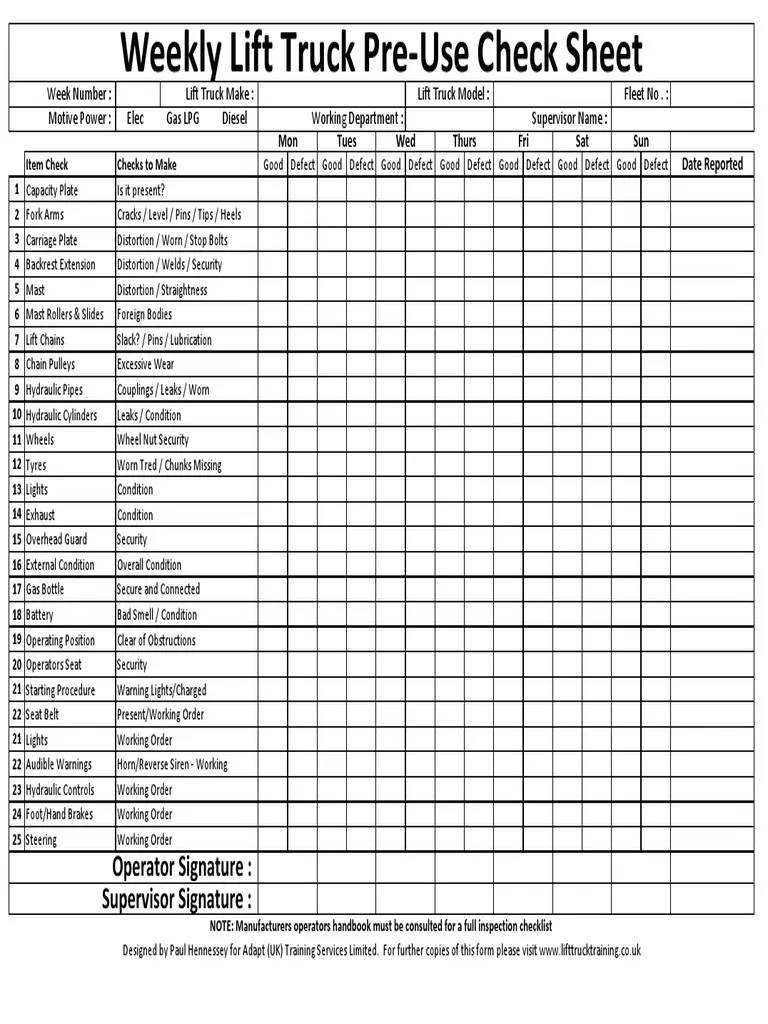

Printable Free Weekly Forklift Inspection Checklist Template

09/2016 deficiency explanations indicate below which line item from the inspection checklist you are referencing. The checklist provides guidelines to identify any potential risks associated.

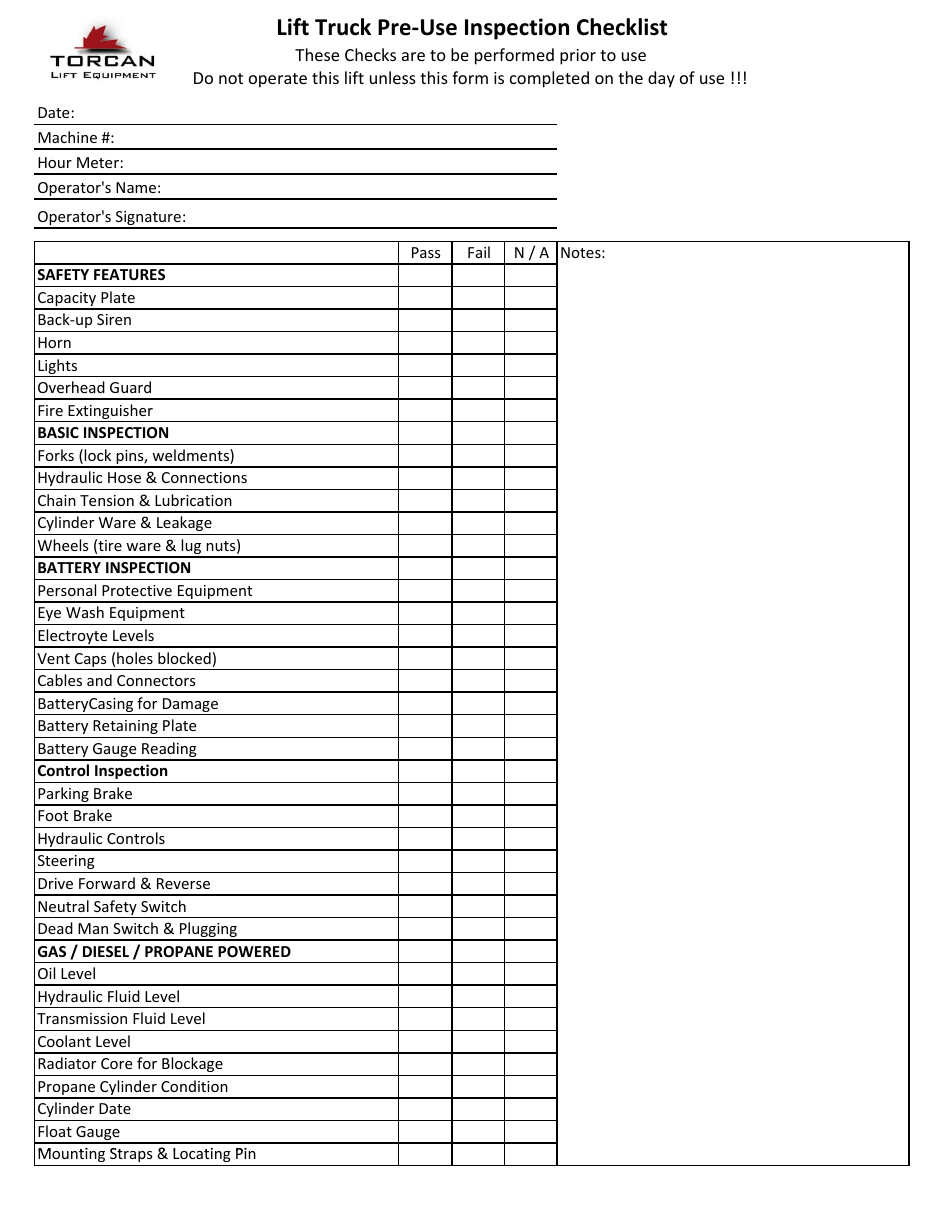

Lift Truck Preuse Inspection Checklist Template Torcan Fill Out

Once all visual checks have been completed, turn the. Web forklift inspection checklist date & time forklift model and/or serial # supervisor name inspector name.

Electric Forklift Preventive Maintenance Checklist, Printable Forklift

Check the battery and connector. You can use this template and framework for your own forklift inspections. Determine fork condition, remembering to check the top.

Printable Free Weekly Forklift Inspection Checklist Template

Users of this template are encouraged to review and. Web forklift/gradall daily inspection checklist to be completed daily by the operator or authorized person before.

Downloadable Checklist For Forklift Inspection (Easy To Use Template)

If the forklift is found to be unsafe, the condition must be reported immediately to the supervisor and repaired. A professional safety inspection is also.

Printable Free Weekly Forklift Inspection Checklist Template

Once all visual checks have been completed, turn the. Assign corrective measures in case damage or malfunction is identified in the forklift. In addition to.

Forklift Inspection Checklist Template Fill Out, Sign Online and

Carefully review each item and mark the corresponding checkbox to indicate compliance or note any observations and areas for improvement. Each component of the forklift.

Check The Braking And Hydraulic Systems.

Each component of the forklift inspection checklist includes two blank lines where the driver may make notes. Every forklift and work environment is unique, and specific inspection requirements may vary based on individual industry practices, regulations, and forklift models. Web forklift inspection checklist date & time forklift model and/or serial # supervisor name inspector name ok = good condition nr = needs repair or item needs review by a supervisor na = not applicable to this particular forklift cks battery & connections fluid level is adequate, vent caps in place; No forklift shall be operated with a leak in the fuel system.

Before Starting The Vehicle, Run Through The List Of Visual Checks On The Left.

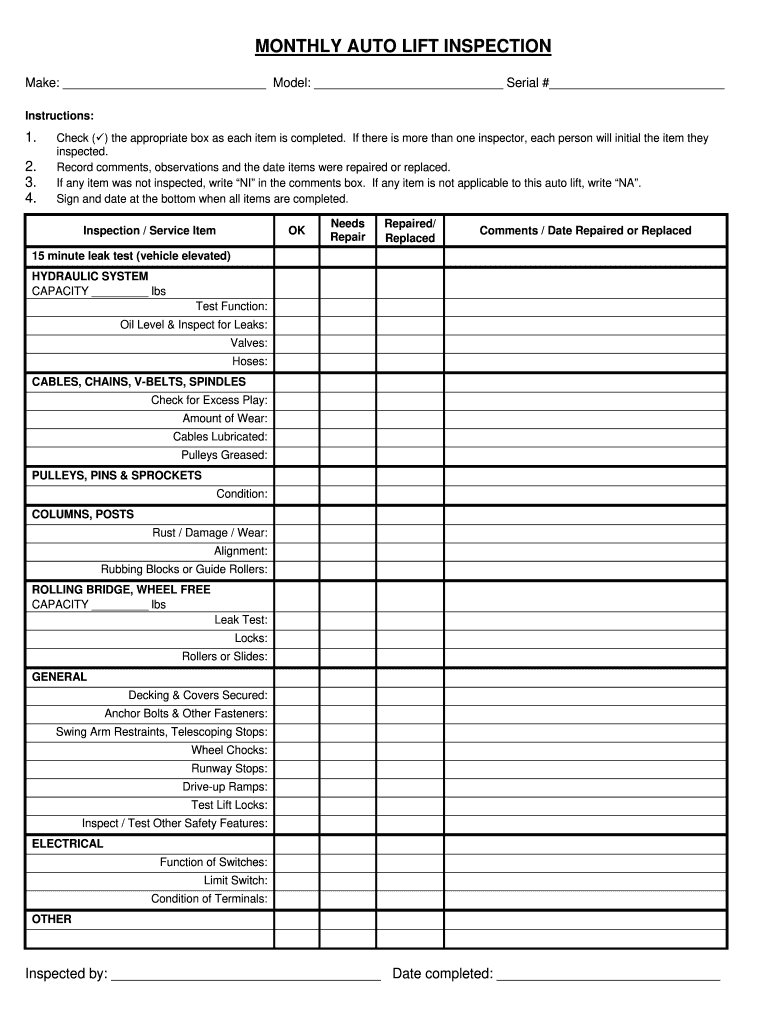

You can use this template and framework for your own forklift inspections. For each “inspection item,” indicate one of the following: Items to be inspected satisfactory condition defective date corrected (if defective) In addition to daily inspections by operators, you need to schedule professional safety inspections a few times per year.

The Checklist Provides Guidelines To Identify Any Potential Risks Associated With Operating The Machine And Can Be Used To Perform Periodic Inspections Of The Equipment.

Web the osha forklift safety inspection checklist provided by safetymint is intended for general informational purposes only. Walk around inspection (warning decals, capacity plate, etc.) forks/locking pins, carriage, mast wheels, tires & lug nuts (condition/pressure) engine (check oil level and for leaks) transmission (check oil level and for leaks) engine belts (check for adjustment/wear. Check the operation of load handling attachments tilt, side shifter, up and down controls. 09/2016 deficiency explanations indicate below which line item from the inspection checklist you are referencing.

If The Forklift Is Found To Be Unsafe, The Condition Must Be Reported Immediately To The Supervisor And Repaired.

For recordkeeping purposes, maintain this form on file when inspection has been completed. Assign corrective measures in case damage or malfunction is identified in the forklift. Web a forklift inspection checklist guides employees where to look during a check process. Web check the safety devices such as seat belts, warning devices, flashing lights and beepers.